GRP Tank Lining Services

Extend the lifespan of your tanks with our advanced composite lining solutions.

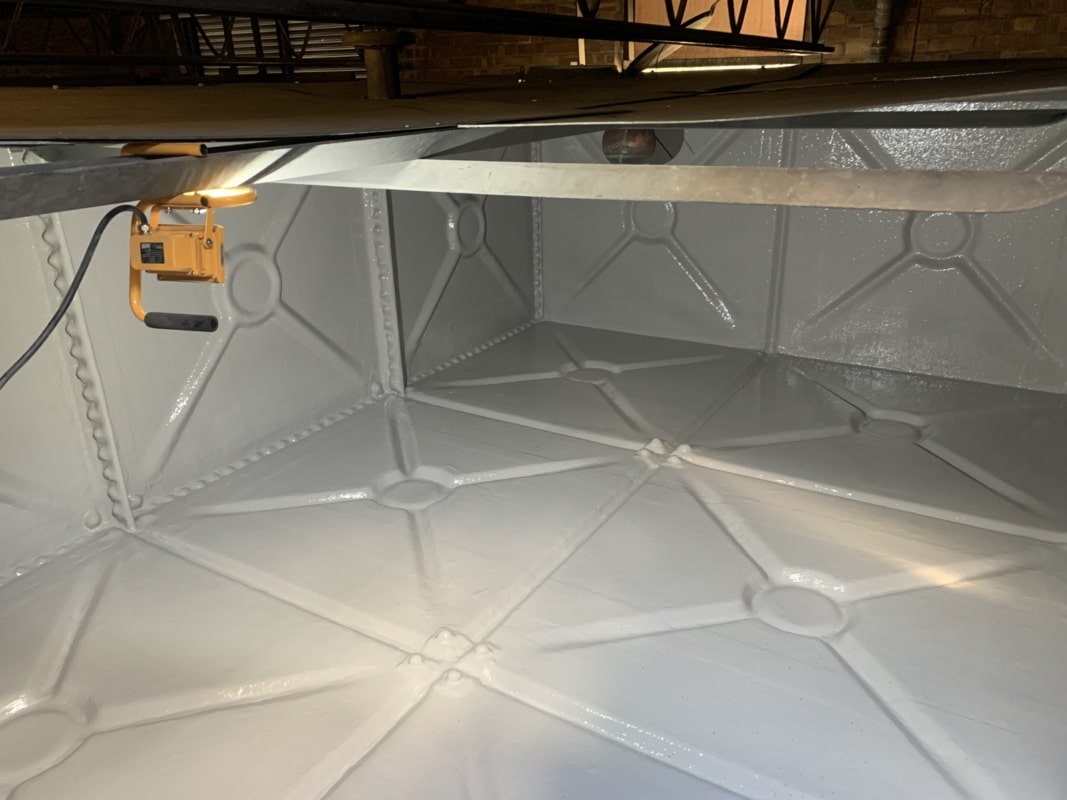

Industrial tanks degrade over time due to chemical exposure, temperature fluctuations, and environmental wear. But before you consider costly tank replacement, there’s a more cost-effective solution — an FRP or GRP tank lining refurbishment from Sui Generis.

Save up to 80% vs. Replacement Costs

Replacing an industrial tank is expensive and disruptive. Our composite lining services offer a reliable alternative at a fraction of the cost — as little as 20% of full replacement — while adding decades to your tank’s operational life.

Acting early can save you thousands. Instead of replacing a damaged tank, our advanced composite refurbishment systems allow us to restore your existing structure quickly and efficiently.

Using a specialist combination of epoxy compounds, polyester pastes, and high-performance composite resins, we can repair everything from cracks and leaks to chemical corrosion and failed joints.

Built to Withstand the Harshest Environments

We custom-blend our GRP and FRP tank linings using high-performance resins and chemical-resistant additives tailored to your tank’s contents — whether it’s water, fuel, chemicals, or effluent.

Our linings are designed for:

- Chemical storage tanks

- Water treatment tanks

- Effluent and wastewater tanks

- Liquor, fuel and process tanks

- Fertiliser and agricultural tanks

- Offshore and marine containment systems

Fast, Seamless Installation

Our skilled team delivers fast, efficient turnaround — with most tank lining projects completed in under a week. From thorough surface preparation to final curing, we handle every stage with precision to ensure a seamless, chemical-resistant, and impact-tolerant finish.

We specialise in preparing all types of substrates — including concrete, steel, and plastic — to guarantee optimal bonding and long-lasting performance. The result is a fully refurbished tank that’s easy to clean, built to endure harsh conditions, and ready for decades of reliable use.

Common Tank Problems – and Our Composite Lining Solutions

Leaking or corroded pipe connections can undermine tank integrity, leading to fluid loss, pressure issues, and potential safety or environmental hazards.

We apply industrial linings around vulnerable joints and connections to create a watertight seal and restore structural integrity.

A damaged or corroded tank lid can compromise the integrity of the entire system, leading to contamination, vapour loss, and increased exposure to environmental elements.

Our team repairs or replaces tank lids using internal or external access methods to restore full functionality and prevent further damage.

Chemical attack can cause significant wall thinning or holes in tanks, compromising structural integrity and increasing the risk of leaks, spills, and hazardous exposure.

After abrasive blasting, we install a custom chemical-resistant GRP or FRP lining (depending on your requirements) that prevents further degradation and contamination.

Leaking sectional tanks can result in fluid loss, structural instability, and potential contamination of the surrounding environment, often due to failed joints or ageing materials.

Composite linings bridge gaps and seal joints, eliminating leaks and reinforcing weak areas for long-term protection.

Why Choose Sui Generis Tank Linings?

- Save Money – Refurbish your tank for a fraction of the cost of replacement

- Long-Term Durability – Up to 20+ year lifespan with minimal maintenance

- Seamless Protection – Eliminates joins and gaps where corrosion often starts

- Tailored Solutions – Linings mixed to suit your tank’s contents and environment

- Chemical & Corrosion Resistance – Proven protection in aggressive conditions

How Composite Linings Work – The Sui Generis Advantage

Steel, concrete, and plastic tanks are vulnerable to corrosion, leaks, and structural failure. Our FRP and GRP tank lining system creates a tank-within-a-tank: a fully bonded, structural barrier that restores integrity, prevents leaks, and resists chemical attack.

Our process includes:

- Surface preparation using abrasive grit blasting

- Crack and void repair with epoxy and polyester compounds

- Application of multi-layer FRP composites

- Curing and final quality inspection