Cooling Tower Lining Services

Extend the life of your cooling towers and reduce the risk of harmful bacteria

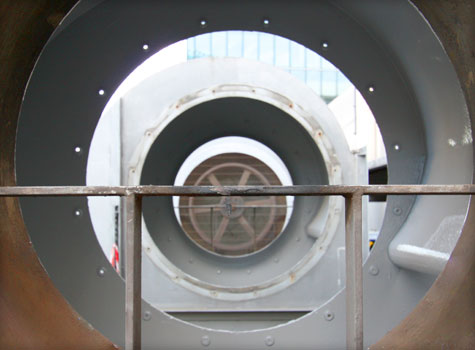

Cooling towers play a vital role in managing temperature and air quality within large buildings. But without proper protection, they can deteriorate rapidly — and create conditions where bacteria like Legionella pneumophila can thrive.

At Sui Generis, we offer advanced GRP and FRP composite cooling tower linings designed to protect your infrastructure, reduce maintenance, and keep your systems safe and compliant.

Restore and Protect with Composite Lining

Cooling towers are exposed to constant water flow and environmental stresses. Over time, inadequate coatings wear away, leading to corrosion, joint failure, and leakage — particularly in stainless and mild steel structures.

Our high-performance GRP and FRP linings form a seamless, chemical-resistant internal barrier that protects your towers from deterioration and bacterial growth. The result? A cost-effective, long-lasting solution that restores performance and prevents expensive replacements.

Why Cooling Towers Fail — and How We Prevent It

- Corrosion of mild steel due to water exposure

- Joint failures in stainless steel units

- Breakdown of inferior coatings like epoxy or bitumen

- Conditions that promote bacterial growth (including Legionella)

Our linings don’t just coat the surface — they create a structurally bonded “tank within a tank” that prevents water ingress, seals vulnerable joints, and offers long-term protection.

Protecting Your People from Harmful Bacteria

At Sui Generis, safety is paramount — and that includes protecting your team and facility from the risk of Legionella and other harmful microbiological contaminants.

The resins used in our GRP and FRP cooling tower linings are tested to BS 6920 standards and have undergone rigorous microbiological testing. They are specifically formulated not to support the growth of bacteria, including Legionella pneumophila, the cause of Legionnaires’ disease.

Once internal surfaces are properly prepared, we apply a seamless, non-porous composite lining that forms a long-lasting, protective barrier. Installed on time and within budget, it ensures your cooling towers stay safe, compliant, and in excellent working condition for years to come.

Benefits of Sui Generis Cooling Tower Linings

- Corrosion-Proof Protection – Prevents rust, joint degradation and leaks

- Bacteria Resistant – Tested to BS 6920 and inhibits Legionella growth

- Durable & Long-Lasting – 20+ year lifespan with minimal maintenance

- Flexible & Seamless – Bonds to all surfaces and withstands structural movement

- Fully Compliant – Approved by WRAS and the Drinking Water Inspectorate

- Fast Installation – Most projects completed on time and on budget

Our Cooling Tower Lining Process

We begin by carrying out a full inspection of your cooling towers to assess their condition and identify any damage, corrosion, or previous coating failures. Our team then prepares the internal surfaces using mechanical abrasion techniques to remove contaminants and provide a suitable key for the new lining.

Next, we repair any damaged joints or surfaces and apply a high-performance GRP (Glass Reinforced Polymer) or FRP (Fibre Reinforced Plastic) lining system, depending on your requirements. This includes multiple layers of chemical-resistant resin reinforced with fibreglass matting to create a seamless, leak-proof and durable internal surface. The lining is designed to tolerate normal structural movement and prevent future corrosion or bacterial growth.

A final topcoat is applied for long-term protection and easy cleaning. Once cured, the surface forms a fully bonded, high-performance barrier that restores the integrity of your cooling tower and ensures compliance with water safety and hygiene standards.