Bund Lining Service

Cost-effective, long-lasting protection for your secondary containment systems

Industrial bunds are exposed to harsh environments and aggressive chemicals. Over time, they degrade — cracking, leaking or becoming contaminated. But before you consider rebuilding, discover a faster, smarter alternative: GRP bund lining solutions from Sui Generis.

Avoid the Cost and Disruption of Bund Replacement

Rebuilding a damaged or degraded bund can be extremely costly, time-consuming, and disruptive to your operations. In many cases, a full replacement isn’t necessary. At Sui Generis, we provide a cost-effective alternative with our high-performance composite bund lining systems, designed to restore structural integrity and extend the service life of existing bunds without the need for demolition.

Our chemical-resistant GRP (Glass Reinforced Polymer) or FRP (Fibre Reinforced Polymer) bund linings are engineered for long-term durability and are suitable for a wide range of industries — including chemical processing, manufacturing, agriculture, water treatment, and fuel storage. Installed by our expert team, most bund lining projects can be completed in less than a week, minimising downtime and allowing your site to return to full operation quickly and safely.

Is Your Bund Still Safe and Environmentally Compliant?

Over time, bunds can become compromised due to wear, chemical attack, weathering, or structural movement. If your bund is showing signs of leaks, cracks, surface degradation or unsealed joints, it may no longer provide effective secondary containment — and could be in breach of Environment Agency (EA) or SEPA pollution control regulations.

Non-compliant bunds not only pose a significant environmental risk through potential leaks and contamination but can also lead to prosecution, fines, and costly downtime if not addressed. In high-risk environments, such as chemical storage or fuel handling areas, the importance of regular inspection and prompt repair cannot be overstated.

At Sui Generis, we offer expert bund assessment, repair and lining services to ensure your containment systems meet current UK environmental compliance standards, including CIRIA C736 and PPG guidelines. Our sustainable FRP and GRP bund lining systems provide a durable, chemical-resistant, and seamless barrier — restoring full containment capability and giving you complete peace of mind.

Long-Term Bund Protection with GRP Lining

Our GRP bund lining systems deliver seamless, corrosion-resistant, and impact-tolerant protection — engineered to withstand aggressive chemical exposure and structural movement. Suitable for both new builds and the refurbishment of existing secondary containment systems, our composite linings offer a long-term alternative to costly bund reconstruction.

Our comprehensive service includes:

- Bund wall and floor repairs

- Crack and joint sealing

- Substrate reinforcement and grit blasting

- Custom resin selection tailored to your stored materials

- Installation of a multi-layer GRP or FRP lining system for maximum durability

We carry out all surface preparation, repairs, and lining work in-house. Most projects are completed within a week, minimising disruption to your operations while ensuring full compliance and long-lasting performance.

Bund Problems? Don’t Replace It — Restore It with Composite Lining

Vegetation growing in bund joints is a sign of cracks or structural failure, allowing stored liquid to escape and putting your site at risk.

We seal the entire structure with a seamless GRP lining that eliminates leaks and restores full containment integrity.

Large cracks compromise the bund’s ability to contain hazardous substances, increasing the risk of environmental pollution.

We repair the damaged substrate and apply a chemical-resistant composite lining to reinforce the structure and prevent future breaches.

Oils, acids, and other aggressive chemicals can penetrate unprotected concrete, leading to permanent contamination and structural degradation.

We install a durable, non-porous FRP lining that prevents future chemical ingress and creates an easy-to-clean surface.

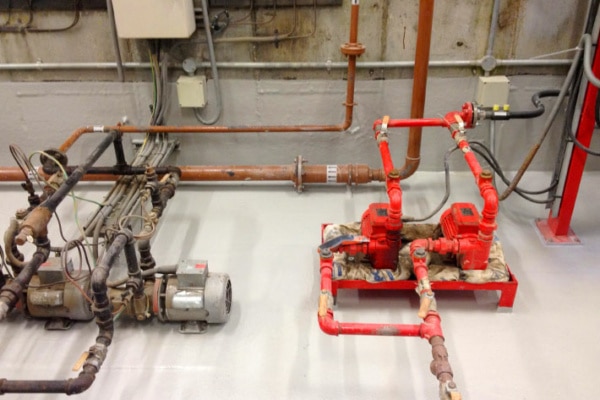

Older bunds often have unprotected pipe entries that act as weak points, allowing liquid to escape and breaching compliance.

We encapsulate all penetrations with reinforced composite layers to form a watertight and regulation-compliant barrier.

Why Choose Sui Generis Composite Bund Linings?

- Long-Term Value – Avoid bund rebuilds with a durable solution

- Chemical Resistant – Handles aggressive and corrosive substances

- Quick Turnaround – Typically installed within 5 working days

- No Weak Joints – Seamless, watertight, impact-resistant

- Trusted by Industry – Over 20 years of experience in high-risk environments

- Fully Compliant – Meets Environment Agency and SEPA regulations

Bund Lining Repair System Overview

Our advanced GRP and sustainable FRP bund lining systems involve building a containment barrier within the existing structure. After preparing the surface through grit blasting and repairs, we apply a four-coat system by hand to ensure full structural reinforcement.

Key benefits:

- Nominal thickness of 3mm with structural strength

- Corrosion and impact resistance

- Flexibility to accommodate structural movement

- Application possible in less-than-ideal weather conditions